Atomization, the process of breaking bulk liquids into small droplets, is common in daily life. Atomization devices such as humidifiers, facial steamers, fog machines, and medical atomizers are popular practical tools offering great help.

Atomization techniques vary with the development of technology. High pressure gas atomization, ultrasonic atomization, microwave heating, and resistance heating are widely applied new techniques. The core of atomization is a coil. As for the materials, ceramics nowadays have been developed to be the essential part of high-quality coils. What are the advantages of ceramics over other materials? How do ceramic coils work? We’ll explore the hidden secrets of ceramic coils.

Why ceramic coils?

Ceramics is not the only material used in coil design. Glass fiber, organic cotton, metallic mesh and other materials all have been widely adopted. The ceramic material used in coils is different from that on our dinner table. It has engineered porous microstructures with special compositions.

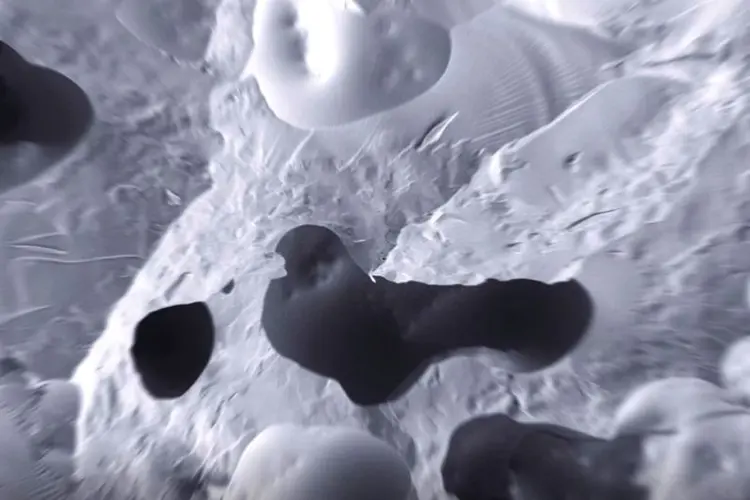

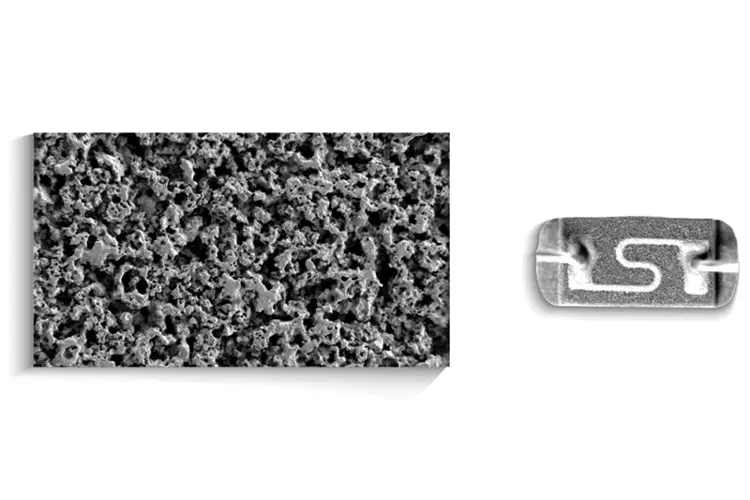

This is a photo of a FEELM Ceramic Coil enlarged thousands of times. As you can see, there are millions of micron size pores in the ceramic cube. The key component of the electronic atomizer is composed of a porous ceramic substrate and a thin layer of metallic film evenly deposited and firmly attached on top of it.

The raw materials used in FEELM coils are processed minerals from nature. After special forming, drying, and high-temperature sintering processes, interconnected micropores are formed inside. The average pore size is about one-fifth of the width of a human hair.

These micropores play a vital role in conducting and locking the e-liquid inside the substrate during the on and off process of vaporization. Thanks to surface tension and capillary action, e-liquid can permeate through the substrate and adsorb on the surface.

The porous ceramic has both strong absorbability and biological compatibility, similar to the activated carbons which are widely used in many household appliances, such as water filters, refrigerator deodorants, facial masks, toothpaste, etc..

What are the advantages of ceramic coils?

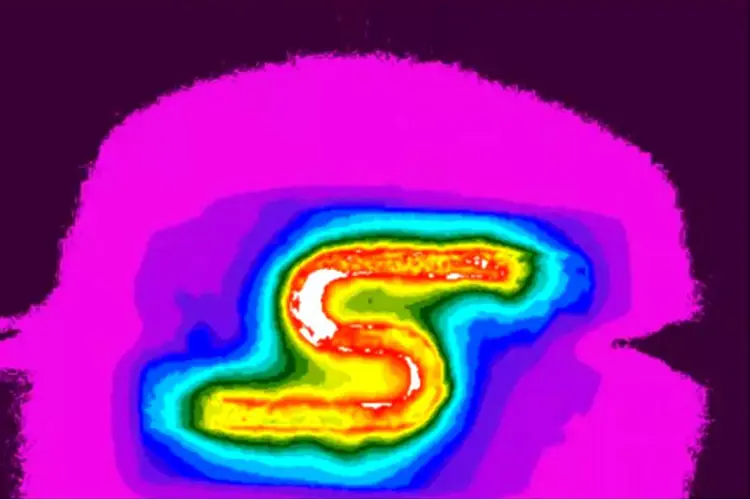

Compared to other materials such as fiber and cotton, the FEELM coil is special in its physical structure, material property and industrial design. These combinations contribute to faster rise in temperature and even temperature distribution on the substrate surface. The precise temperature control enabled by the FEELM can greatly reduce the amounts of aldehydes and ketones produced during the vaporization.

The FEELM coils are composed of a ceramic substrate and a layer of metallic film. The ceramic is sintered at a high temperature and formed into the shape of a bowl. The metallic film is printed onto the substrate surface with an “s-shape” in order to provide efficient and even heating, similar to the way stoves heat up pots in cooking. The atomizer vaporizes the e-liquid into vapor while heated by the metallic film with precise temperature.

Another advantage of FEELM is that the even heating can effectively eliminate most of the partial carbonation and reduce the burnt taste problem which has troubled the industry for a long time.

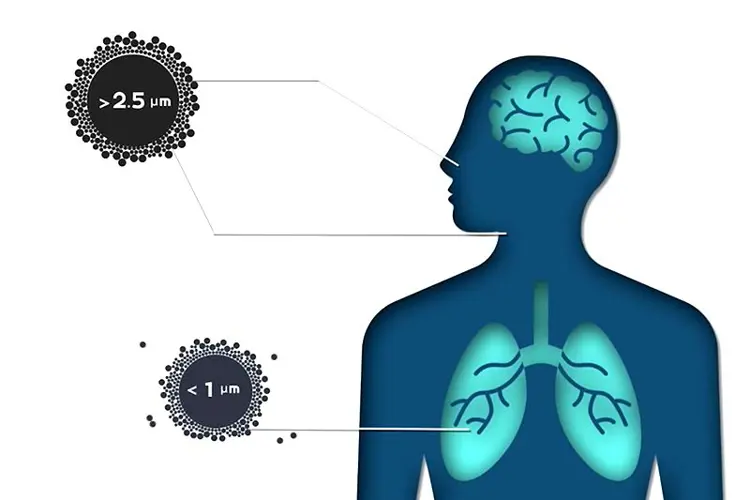

Atomization technology has been used in medical applications for long, such as orally inhaled drugs for treatment of seasonal asthma. The size of particles produced in regular atomization can vary greatly. Among these, particles smaller than 2.5 μm can be readily deposited in the human respiratory tract and oral cavity, and those smaller than 1 μm can be absorbed by the lung. The aerosol particles produced by FEELM ceramic coil are smaller than 1μm, which leads to better lung absorption, more intense flavor, and greater satisfaction.

In summary, the electronic atomizer is not the only application of the ceramic coil. With more fundamental research and development of next-generation advanced atomization technology, more product applications of the ceramic atomizer may be expected and soon could become part of our daily life!