Today, in 2023, e-cigarettes are the most innovative technological product of the 21st century, introducing the concept of environmental health and breaking away from the monopoly of traditional cigarettes.

Certain breakthroughs have been made in some technical areas, such as ceramic cores, as a result of continuous exploration by major vape brands. Nonetheless, they still face numerous pain points in terms of taste experience, raw material safety, and service life, which significantly impact the consumer experience.

As a leading vape tech company, Geekvape introduces its a brand new vaping technology solution: VPU. VPU stands for Vaping Processing Unit. This technology platform integrates the most recent advancements in fluid and thermal transmission, material safety, and advanced material research to provide a comprehensive solution for customers. Specifically, VPU can be introduced from these three aspects: Vape experience, safety performance and unit process control

Vape experience

Geekvape has the leading edge in heat-generating devices such as etched heaters, non-woven, ceramic cores, etc., and combine their expertise in simulation testing, material micro design, device structure design, and other areas of technical competence.

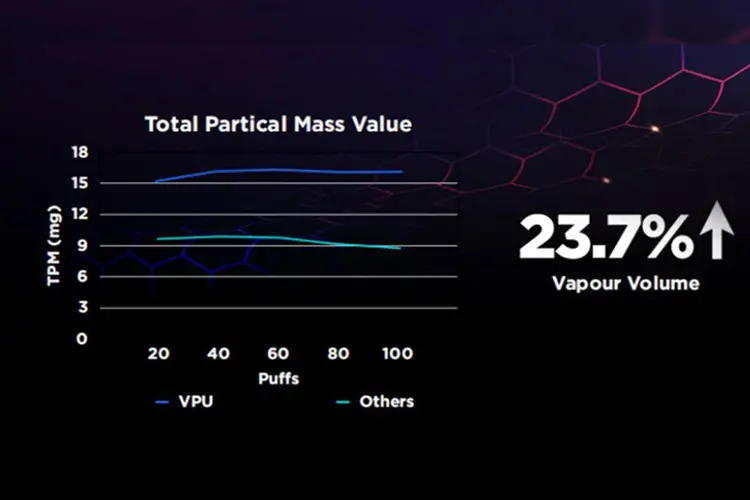

As is common knowledge, heat generators are one of the most essential components of electro-atomization, and their design and manufacturing quality have a direct impact on vaping quality as a whole. The heat generators of the VPU are calibrated using finite element analysis (FEA) in conjunction with infrared imaging, aerosol particle size analysis, Total Partical Mass, and other advanced testing methods to ensure the optimal design of heat generators and the desired release of aerosol to achieve high taste restoration, fine texture, and consistent vaping performance.

According to the aerosol composition test results, the product adopting the vpu technology had a vapour volume increase of 23.7% with the same number of puffs compared to other products on the market. As the number of puffs increases, the aerosol release is stable and the taste continues without degradation, which means that each puff provides the user with a consistent flavor restoration.

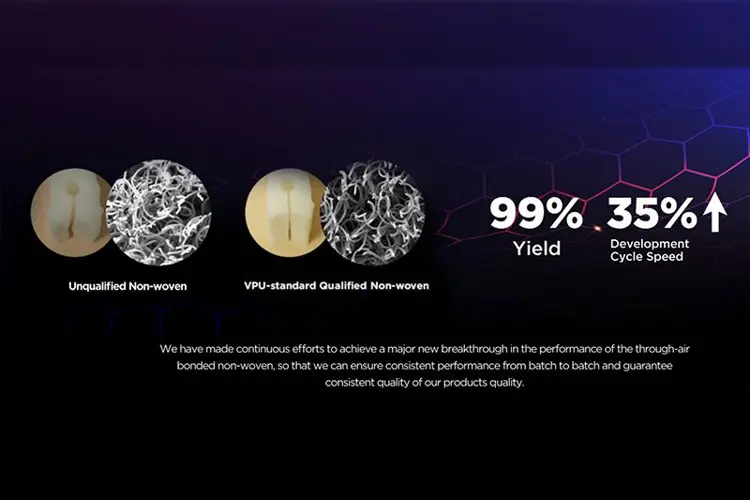

For disposable vape range and vapor volume, The through-air bonded non-woven can be said to be the most important. The market is restocked with various standards, and each manufacturer has a distinct tuning pilot. Leakage and heterogeneous permeability are the most prevalent disadvantages of these low-quality nonwovens, which will ultimately result in a very high rate of defective products, not only causing severe after-sales issues, but also increasing the costs.

Geekvape has thus far developed Non-woven, which has a higher liquid conductivity and storage rate. Geekvape has been developing new materials and production processes from the ground up in an effort to achieve greater consistency and stability, and has been actively collaborating with top textile universities to advance technology. Compared to the previous ones, Geekvape has created industry-leading testing standards in terms of technology to test the performance of liquid storage cotton in terms of size, density, liquid absorption rate, and liquid conductivity.

According to geekvape's chief marketing officer, Potti Lan, Geekvape’s yield rate has improved from 85% to 99% and our development cycle speed has increased by 35%.

“ I am proud to say that we are the first company in the industry to follow a high standard of multi-dimensional testing, and we have made continuous efforts to achieve a major new breakthrough in the performance of the through-air bonded non-woven, so that we can ensure consistent performance from batch to batch and guarantee consistent quality of our products.”

In recent years, the coil technology has continued to develop, there have been significant advances, market customisation criteria differ. And what we are concerned about the coil are the flavor restoration, harm reduction and liquid leakage prevention.

Speaking about liquid soaking and storage, Geekvape’s R&D team has improved the coil matrix's liquid soaking and storage capacity by using oleophilic materials with tunable nano-microscopic morphology. This has improved the coil matrix's flavor and prevented stuck core.

When choosing heating materials and designing heating patterns of the coil, the heating speed, heating concentration and corrosion resistance of the materials are all taken into account.

Geekvape uses advanced raw material selection and molding processes to achieve precise control of pore size in the range of 0.1 to 80 microns in its research of ceramic cores. This enables them to match the optimal pore size with a uniform pore structure for a variety of application scenarios. At the same time, Geekvape has implemented the simulation experiment platform. Simulation design and repeated trials are used to find the ideal combination of high safety along with excellent taste.

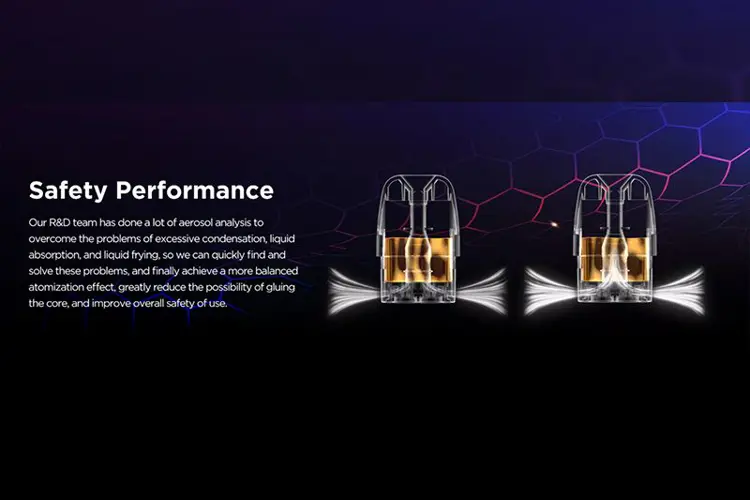

Safety performance

Geekvape has taken a multi-dimensional approach to the selection of raw materials, testing of ingredients, and thermal safety performance to demonstrate the safety guarantee of VPU.

By using an electron microscope to determine the internal composition of the heating wire and cotton interior, they can obtain the elemental energy spectrum.

This ensures that our raw materials do not contain heavy metals, and Geekvape's testing procedures rigorously adhere to the ROHS regulations. In addition, Geekvape is adopting the infrared imaging technology to verify the temperature field of the heat generators in order to ensure the safety of the heat generation performance.

Geekvape's R&D team has performed extensive aerosol analysis to overcome the problems of excessive condensation, liquid absorption, and frying. As a result, they are able to quickly identify and resolve these issues, achieving a more balanced atomization effect, reducing the likelihood of gluing the core, and enhancing overall user safety.

Unit process control

Unit process control is the third element of the vpu, and its purpose is to implement statistically based process control at every stage of the process in order to ensure batch-to-batch consistency of quality. At the press conference, Geekvape demonstrated its highly automated production with a 99.95% yield rate and a monthly production volume of 200 million.

According to Charles Li, the product line executive of Geekvape, “Our new series - Geekvape Q and Geekbar Meloso, which have been built in compliance with the vpu standard. Vaping is a comprehensive solution instead of a single point technology, and no single point technology can provide consumers a complete vaping experience. ”

VPU focuses on the overall atomization system solution rather than simply one particular cutting-edge technology.This will elevate the vaping industry even further.

President Trump promised during his election campaign to “save vaping," but his administration has undermined that goal at every turn.

The U.S. disposable vape market has grown to $2 billion in annual sales, although nearly none of the products are authorized by the FDA.

More than 30 bills that would impose severe restrictions vaping consumers’ product choices remain active in U.S. state legislatures.

The Freemax REXA PRO and REXA SMART are highly advanced pod vapes, offering seemingly endless features, beautiful touchscreens, and new DUOMAX pods.

The OXVA XLIM Pro 2 DNA is powered by a custom-made Evolv DNA chipset, offering a Replay function and dry hit protection. Read our review to find out more.

The SKE Bar is a 2 mL replaceable pod vape with a 500 mAh battery, a 1.2-ohm mesh coil, and 35 flavors to choose from in 2% nicotine.