Smart manufacturing integrates a new generation of information and communication technology with modern manufacturing technologies in order to attain comprehensive intelligence in R&D, design, production, supply, and service. A growing number of significant manufacturing organizations are transforming and enhancing intelligent manufacturing in response to the demand for digitalization, which enables businesses to reach customers more directly, respond to market demands more rapidly, increase production efficiency, and use fewer resources.

Geekvape saw early on the significance of smart manufacturing for increasing their core competencies and acted accordingly. Geekvape has amassed the resources to perform creative and cutting-edge technology research in recent years, ushering in an era of fast growth. As a result, it has become one of the leading companies in the worldwide e-cigarette sector, exporting its GEEKVAPE and GEEKBAR products to more than 70 countries.

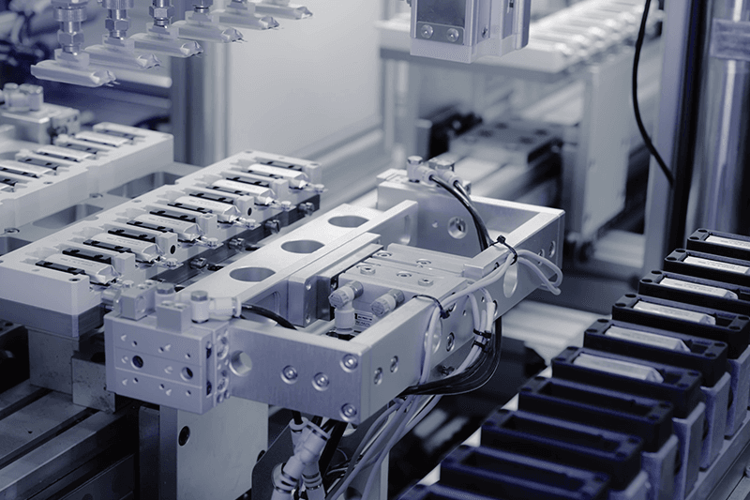

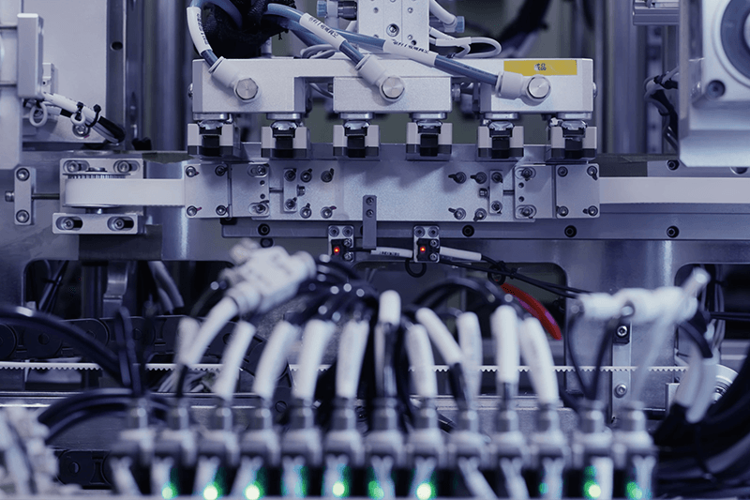

Geekvape, a prominent manufacturer of electronic atomization technologies, has implemented a lean, information-based, automated production method. The company has used lean production and standardized process management in order to create an industry-leading lean supply chain model and higher-quality goods and services for its clients. Geekvape's supply chain management system integrates capital, commercial, and informational movements with logistical ones. The company is largely automated, expanding production capacity and attaining intelligent product production thanks to a big automatic assembly line packaging process. To visit: https://fb.watch/h5qjcg_GsB/

According to reports, Geekvape is in the process of constructing an industrial park within the Zhuhai National Hi-Tech Industrial Development District in Guangdong province. The park, which is a collaborative effort with the atomization technology company QISITECH, is said to be an ambitious undertaking.

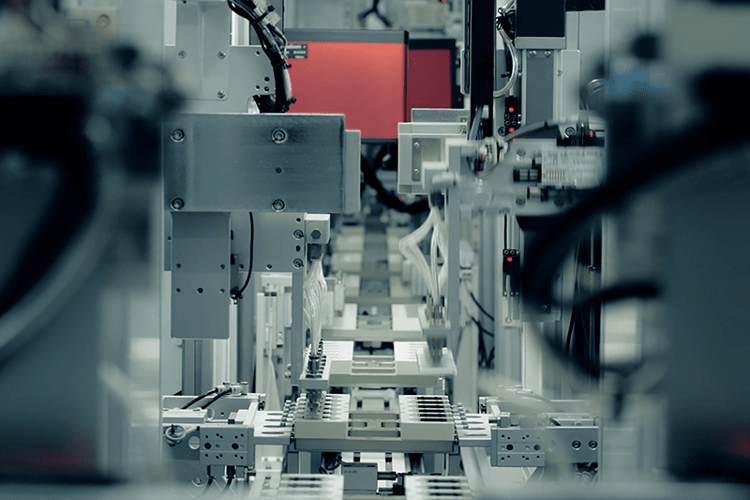

The entire project is anticipated to be finished within two years. QISITECH’s involvement covers research and development, manufacturing and distribution of electronic atomization equipment, alongside clean, dust-free facilities for trial production, assembly, preparation for liquid filling and packaging.

The new industrial park will be more than 15 times larger than Geekvape's current Zhuhai location, which is 14,000 square meters and contains three standard workshops and over 80 production lines.

"Digitization and smart manufacturing will offer great benefits, not just in production volume and efficiencies, but also in assuring consumers around the world that our products are made to consistently high-quality standards and can be enjoyed safely," said Allen Yang, CEO of GEEKVAPE.

“The integrated packaging technology and three-level QR coding introduces a higher level of traceability to defeat counterfeit and illicit sales.”

This transparency of product information, supported by online automatic detection, with an alarm, analysis and diagnostic system, assures the traceability of products through the information stored on each batch.

Smart manufacturing has improved Geekvape Technology's competitiveness, allowing it to become an inventor, pioneer, and enabler of smart manufacturing for e-cigarettes. In addition to providing Geekvape's with positive financial results and delivering overall improvements in cost containment, quality, and efficiency, it has the potential to advance energy conservation, environmentally friendly production, and positive social outcomes.

President Trump promised during his election campaign to “save vaping," but his administration has undermined that goal at every turn.

The U.S. disposable vape market has grown to $2 billion in annual sales, although nearly none of the products are authorized by the FDA.

More than 30 bills that would impose severe restrictions vaping consumers’ product choices remain active in U.S. state legislatures.

The Freemax REXA PRO and REXA SMART are highly advanced pod vapes, offering seemingly endless features, beautiful touchscreens, and new DUOMAX pods.

The OXVA XLIM Pro 2 DNA is powered by a custom-made Evolv DNA chipset, offering a Replay function and dry hit protection. Read our review to find out more.

The SKE Bar is a 2 mL replaceable pod vape with a 500 mAh battery, a 1.2-ohm mesh coil, and 35 flavors to choose from in 2% nicotine.