Beyond nicotine satisfaction and cloud chasing, vaping is very much an exploration of our perception and appreciation of flavors. How we perceive flavor is quite complex. From the perspective of taste, there are 6 flavors that can be categorized: sweet, sour, salty, bitter, pungent, and astringent. Not just linked to our tongue, flavor is also something you can smell. According to the NIH, humans can distinguish more than 1 trillion scents. It goes without saying then, that in improving refillable vaping devices, we are also pushing the frontier of flavor delivery.

From the invention of the first vaping device until now, flavor has become an essential part of the vaping experience.

Nowadays, vaping is more than just cloud chasing. Vape juice is available in a wide array of flavors, ranging from tobaccos, to fruits, candies, desserts, menthol, and everything in between.

However, while the vape juice provides the flavor, the vaping device is the key to unlocking and delivering it in the form of flavorful vapor.

Flavor is the art of temperature

For years, scientists have been exploring how to fully unlock the full potential of vaping flavor. Dr. Yu Zhou, a scientist from SMOORE Lab, said, “We’ve collected and tested thousands of liquids from the market just to discover how vaping devices can deliver the best flavor. We’ve come to some interesting conclusions from our research, but most importantly, we can say that flavor is the art of temperature.”

Dr. Zhou has been working for years for SMOORE’s sub-brand, VAPORESSO, to continuously improve temperature control and its products’ flavor delivery. “All vape devices from the beginning of vaping til now share the same basic heating mechanism. This includes some kind of storage for the e-liquid, a heating coil and a wick. When you heat up the coil in a device, the heat will vaporize the e-liquid from the wick, delivering it to the user. Typically the range that users tend to vape at exists anywhere from 100°C - 315°C. But at the lower end of this range the vapor and subsequent flavor is pretty weak, and at the higher end puffs are harsh and the flavor can degrade from the PG breaking down into formaldehyde.”

“There exists a smaller temperature range in between these extremes—the ‘sweet spot’ if you may—in which users will experience ideal flavor delivery that is strong," added Dr. Zhou. "That range gives an accurate representation of the e-liquid’s flavor profile while remaining smooth. After thousands of tests with thousands of flavors from different manufacturers, we found that the zone of best flavor expression exists between 200°-260° C, depending on the juice.”

Flavor delivery

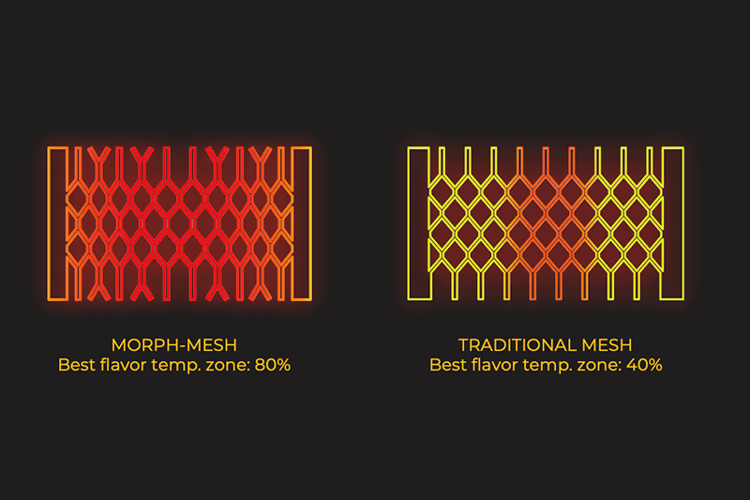

“With the recently developed COREX technology, we hope to solve the problem of inconsistent heating and flavor delivery," said Dr. Zhou. "Using a new MORPH-Mesh coil design with a greater surface area for heating, a larger ratio of the coil can reach the optimum flavor delivery temperature. For users, this translates to bigger, more flavorful clouds.”

Flavor consistency

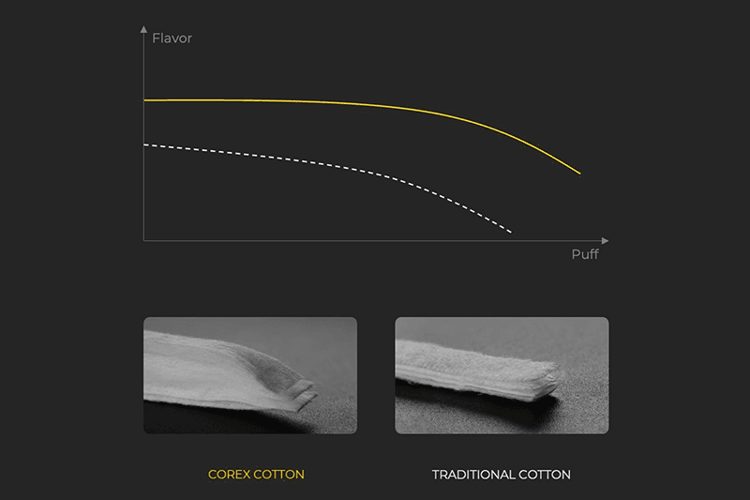

You might have experienced that perfect flavor before, just to have it degrade over time as the cotton core loses its ability to retain liquid. While a step up from older silica-based wicks, organic cotton wicks still suffer from significant liquid retention degradation over time. Unfortunately, to find a cotton that sidesteps this issue, we have to go back to the drawing board.

“We’ve checked all cotton materials in the market, but couldn’t find any that fit our requirements. So we decided to make one of our own,” Dr. Zhou said. In adopting the industry’s first 3D spunlace process, Zhou’s team succeeded in making a patented COREX cotton wick. Comprised of microfibers which give it a cloud-like fluffy texture and greater surface area, COREX cotton abstracts e-liquid more efficiently, thoroughly, and evenly compared to standard cotton wicks.

“According to lab tests, the COREX cotton’s flavor retention is 40% higher than that of traditional cotton, and has a service life 20 % longer than that of a traditional cotton core. For users, this means every puff carries the same flavorful punch, even after longer use,” Dr. Zhou added.

Leaking corrupts flavor

Most have experienced it. Sometimes that puff comes with that extra spicy, weird flavor, you never want to taste. Of course we’re talking about those unfortunate instances where device leakage results in e-juice being inhaled directly into the user’s mouth. While the flavor from vape juice can be pleasant in its vapor form, it can be overwhelming in its liquid form. While 100% leak protection is still a work in progress, several vape manufacturers have improved upon this issue, introducing several of their own proprietary leak protection technologies in recent years.

COREX in practice

“So far, we’ve managed to implement COREX technology in VAPORESSO’s LUXE X kit,” said Dr. Zhou. “From our lab tests, we can already see marked improvements, including a 50% increase in vaporization efficiency ratio, a 50% increase in flavor and vapor reproduction, and a 50% jump in pod lifespan.”

In the past 2 decades, vaping tech has been advancing at breakneck speed. As the next generation of vaping development is upon us, what new advancements in the frontier of flavor can we expect? Whatever it may be, it will certainly be exciting to see.

President Trump promised during his election campaign to “save vaping," but his administration has undermined that goal at every turn.

The U.S. disposable vape market has grown to $2 billion in annual sales, although nearly none of the products are authorized by the FDA.

More than 30 bills that would impose severe restrictions vaping consumers’ product choices remain active in U.S. state legislatures.

The Freemax REXA PRO and REXA SMART are highly advanced pod vapes, offering seemingly endless features, beautiful touchscreens, and new DUOMAX pods.

The OXVA XLIM Pro 2 DNA is powered by a custom-made Evolv DNA chipset, offering a Replay function and dry hit protection. Read our review to find out more.

The SKE Bar is a 2 mL replaceable pod vape with a 500 mAh battery, a 1.2-ohm mesh coil, and 35 flavors to choose from in 2% nicotine.